OGC Energy leads the way in CO2 transportation and storage

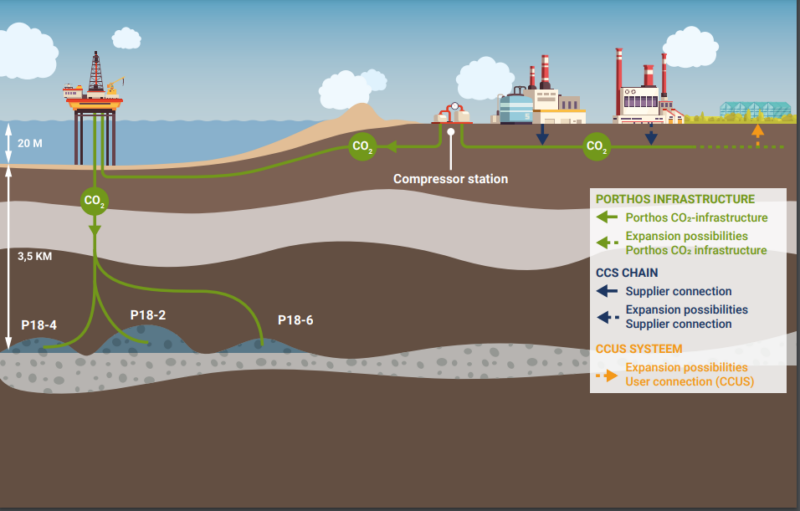

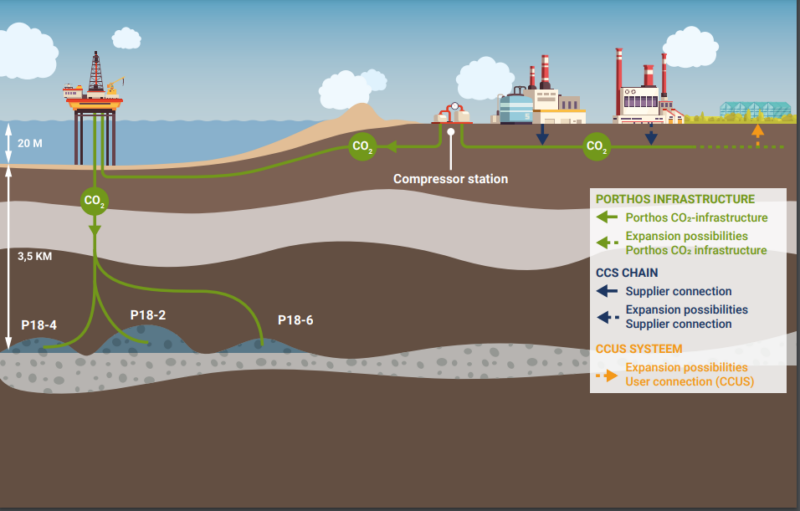

The Porthos project has the potential to make a significant contribution to helping the Netherlands reach its carbon reduction targets.

The Challenge:

Porthos CO2 Transport and Storage in the Netherlands struck a deal with OGC Energy to complete a full corrosion risk assessment and identify the effect of impurities on all possible damage mechanisms for CO2 transport vehicles.

This assessment was the first of its kind, considering the CO2 feed from different industrial sources in the Rotterdam area. Porthos will store around 37 MtCO2, approximately 2.5 MtCO2 per year, for the next 15 years.

Porthos needed to identify the corrosion risks associated with multiple impurities of Carbon Capture, Utilisation, and Storage (CCUS). This step is crucial to completing the first European project to transport CO2 across Europe for final capture in an empty gas field beneath the North Sea.

How OGC Energy added value:

OGC Energy was the only company with the expertise to understand the project’s novel challenges. They evaluated, identified and provided recommendations regarding the corrosion risks of CCUS associated with multiple impurities.

OGC Energy’s work concluded that Porthos transport pipelines can now be used with carbon steel as the primary construction material. This was influential in securing the project’s continuity without the prohibitive cost of alternative and expensive materials whilst maintaining the highest safety standards.

In this complex project, OGC Energy faced the challenge of efficiently conducting the corrosion study to ensure there would be no delays in the Final Investment Decision (FID). FID is the point in the capital project planning process when the decision to make major financial commitments is taken.

With this in mind, OGC Energy proposed to Porthos that the CO2 specification must be refined as safe limits for impurities were identified. Finalising the new CO2 specification, the Porthos project became more flexible for new CO2 emitters (CO2 emissions that tie into the project).

Why corrosion expertise is important in the UK CCUS industry?

The safety of CCUS projects is one of the most important issues with large-scale applications. There are cases in high-profile CCUS projects where contaminants in the stream have caused extreme corrosion. OGC Energy’s corrosion and material expertise have helped the industry understand carbon capture risks and the required solutions.

Some operators need to carbon offset their other operations until CCUS facilities work to full capacity. This can be financially expensive for the company. Furthermore, not managing the corrosion risk in the early stages could result in potential loss of life as the highly pressurised carbon dioxide displaces air in the immediate vicinity. With a corrosion specialist like OGC Energy to provide guidance and reassurance, operators/asset owners in the industry can demonstrate appropriate risk protections for preventing external and internal corrosion.

OGC Energy has gained a better understanding of future CCUS projects’ needs, and this breakthrough will provide valuable knowledge into the industry. OGC Energy’s track record could be worthwhile for the industry. Its level of expertise can potentially contribute to the UK’s industry drive to become a world leader in the development of capturing and storing harmful carbon dioxide emissions away from the atmosphere.

Find out more:

https://ogcenergy.com/

Email: [email protected]

Telephone: +44 114 4000850