Flexible Pipe Integrity Management

Guidance, data and lessons from decades of industry experience in flexible pipe integrity management.

Flexible pipe integrity has been a long-standing focus for industry collaboration and improvement.

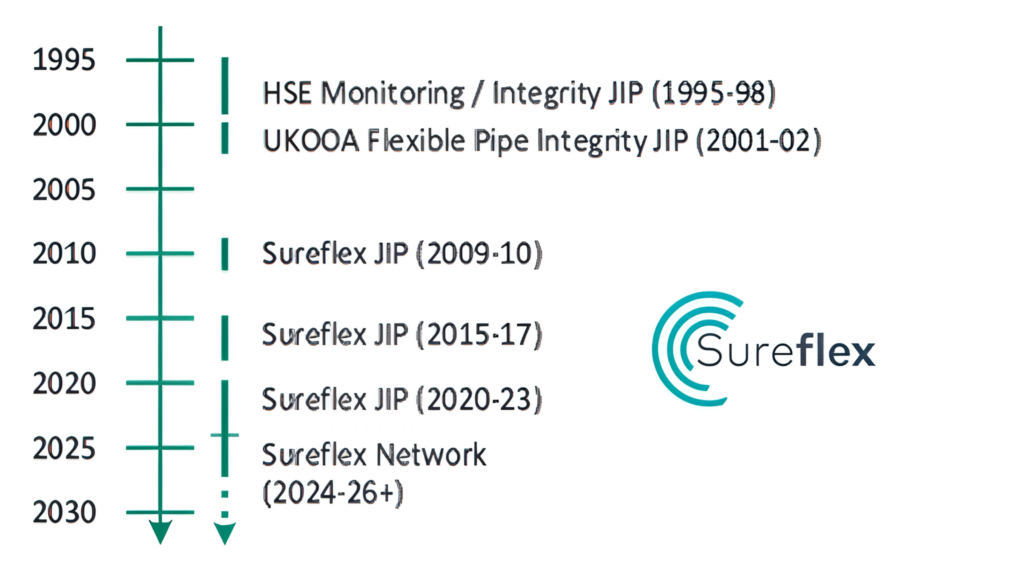

Over more than 30 years, Flexible Pipe Integrity Management guidance has been developed through a series of Joint Industry Projects (JIPs) led by Wood (and its predecessor organisations), with contributions from OEUK’s predecessors, including O&G UK and UKOOA. These initiatives draw on over 50 years of operational experience and lessons learned.

OEUK is pleased to share links to these resources to support wider industry learning.

- Summary

- Important Notes

- Contributors

Unbonded flexible pipe remains a vital technology, with use expanding into more demanding applications despite its maturity since the 1970s. Manufacturers continue R&D to meet evolving needs, although a few new failure modes have emerged.

This latest project and guidance provide key datasets and insights, including:

-

A population database covering over 22,500 pipe sections and 20,500+ km of flexible pipe

-

Nearly 900 documented damage/degradation events spanning ~50 years, most (~80%) not resulting in loss of containment—demonstrating the pipes’ robustness even under abnormal conditions

-

Good practice guidance on inspection, monitoring, maintenance, and repair to support effective integrity management

-

Lessons learned across all life cycle stages and a summary of current industry technology developments

-

This guidance is not a regulatory or minimum requirement document. It promotes risk-based integrity management—good practice should be applied as appropriate.

-

Recommendations are based on consensus from the JIP steering committee, though not all members may agree on every point.

-

No warranties or liabilities are assumed by Wood Group UK Ltd or contributing parties regarding the accuracy or use of this information.

For further information, contact:

Ian Macleod (Wood): [email protected]

Keith Wise (OEUK): [email protected]

-

01. Operators of Flexible Pipe

- BP

- Chevron

- CNRI

- Equinor

- ExxonMobil

- Harbour Energy

- Inpex

- Petrobras

- Petronas

- PetroRio

- Santos

- Shell

- Woodside Flexible Pipe

-

02. Manufacturers

- Baker Hughes

- NOV

- TechnipFMC

-

03. Trade Body & Regulatory Authorities

- Offshore Energies UK

- Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP) – Brazil,

- Health & Safety Executive (HSE) – UK,

- National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) – Australia

- Petroleum Safety Authority (PSA) – Norway

Useful Links

Wood SureFlex Report: Flexible Pipe Integrity Insights (December 2023)

Explore Wood’s insights on flexible pipe integrity, highlighting risks, solutions, and best practices.

Advancing Subsea Pipeline Integrity Assessment

Explore innovative methodologies for evaluating subsea pipeline integrity, focusing on enhancing safety and reliability in offshore operations.

SureFlex JIP: Latest Insights on Flexible Pipe Integrity

The SureFlex Joint Industry Project offers updated data on unbonded flexible-pipe populations, damage statistics, and integrity management practices.