An integrated approach to heat treatment

A smart approach to a UK refinery-wide turnaround proved its value, saving the client 36% in labour costs.

The Challenge:

Performing heat treatment services during a refinery-wide turnaround for one of the largest petroleum companies in the United Kingdom.

During planning stages, the project posed significant challenges as the client had limited knowledge regarding the scope of work, due to the majority of the work being inspection driven. This presented complications for the company’s intended work timeline during the turnaround.

The Response:

Superheat was founded on the principles of a safer and more efficient way to provide on-site heat treatment services. Today, Superheat is leading the heat treatment industry by integrating emerging communication technology, equipment advances and innovative software solutions. Through its Superheat SmartWay™ approach and its Superheat SmartView™ QA platform, control of the heat treatment process is consistent at all levels. Superheat manages on-site quality via remote monitoring technology, eliminating the need for non-productive monitoring personnel on the job site. This, in turn, reduces on-site labour requirements by up to 40% while mitigating safety concerns.

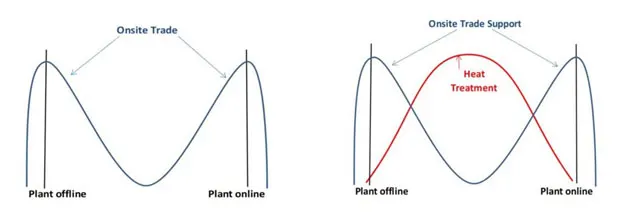

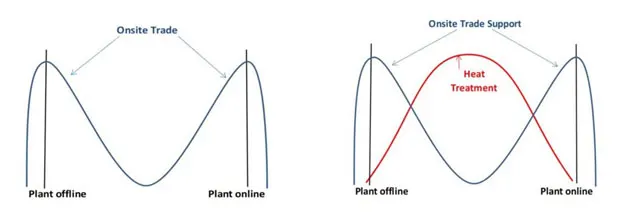

Refinery project delivery: Implementing the Superheat SmartWrap™ programme, six Superheat supervisors from the UK were present on site with 24 contracted insulators. The insulators underwent Superheat’s 16-hour heat treatment course prior to the turnaround. Combining training with Superheat SmartCenter™ monitoring produced further reductions in on-site labour, with Superheat remotely overseeing the process. Using Superheat SmartView™ QA platform – an interactive web-based quality assurance platform including everything from client requests and live weld status & charts to final Superheat SmartReports™ QA package download to provide project data in real-time – technicians were able to troubleshoot heat treatment cycles in progress while maintaining a high level of quality. The insulators were only utilised for the wrapping and stripping of welds, which accounts for 33% of the heat treatment procedure.

With the new Superheat SmartView™ QA platform, users simply upload heat treatment requests, quality & engineering specifications, IOS drawings and other materials into the drop-in box. This dramatically improves responsiveness and saves valuable time premobilisation. Clients can view activity status and the estimated start-time for jobs being set up for heat treatment, providing enhanced decision-making abilities as they plan the next steps on the project. SmartView™ also helps ensure the job is done right, first time by adding an optional hold point for additional QA inspection. Clients can monitor live heat cycle charts and status updates in real time from any device. SmartView™ also ensures QA parameters are adhered to, offering the highest level of transparency compared to any heat treatment provider. Clients can then further quantify their heat treatment at the individual weld level by downloading a complete Superheat SmartReports™ package that compiles all activities to the weld in one file or in separate files.

The Result:

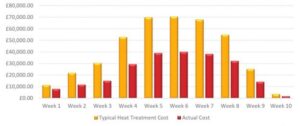

By utilising the contractors on an as-needed basis and taking advantage of the Superheat SmartView™ QA platform, the client obtained a labour cost saving of 36% overall. The adjusted “wrench time” for the general insulation contractor was increased by only 3%.

Weekly Manpower Savings:

Find out more:

www.superheat.com

Contact:

+44 (0) 1462 88803