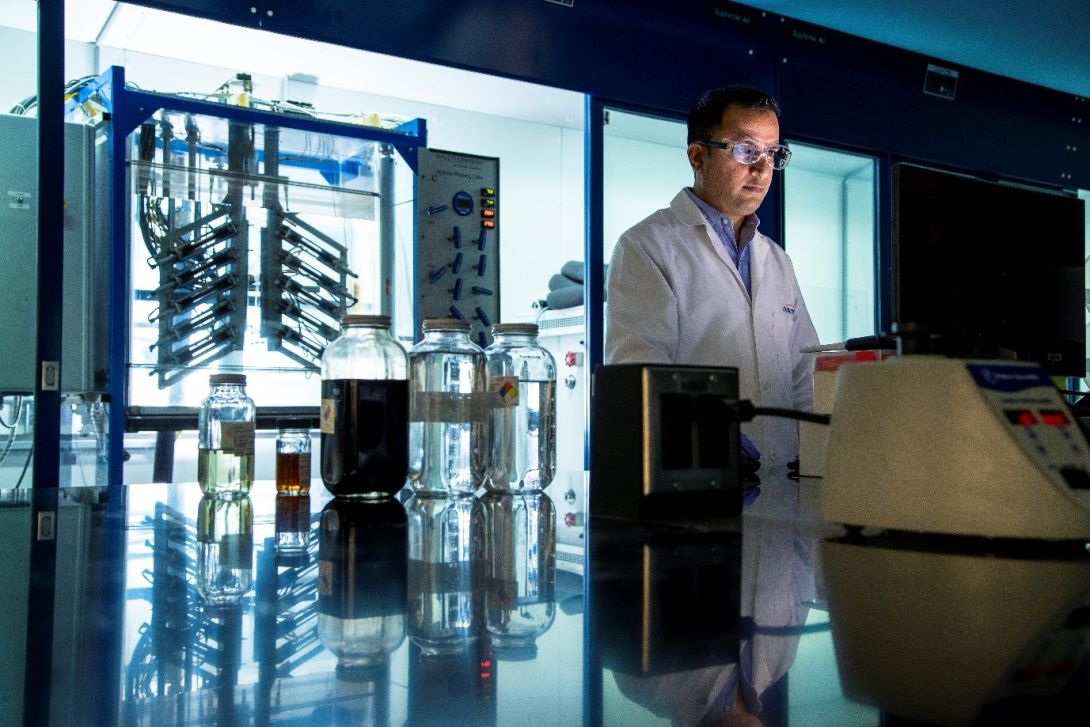

Creating the right chemistry to cut carbon footprint

Smart chemical engineering techniques are proven to help in reducing greenhouse gas emissions.

The Challenge

Reducing the carbon footprint associated with transporting chemical supplies for offshore operations. The logistics of transferring production chemicals from an onshore plant to an offshore platform contribute to rising emission levels.

The Response

ChampionX has developed a smarter approach to product engineering. Its two-pronged approach reduces the volume of chemicals required in transportation. The company does this by designing and selecting chemistries to contain a higher activity percentage, improving the effectiveness of the product per quantity used and then combining the functionality of multiple products into a single product.

This approach has been used at various international locations to reduce costs whilst sustaining the environment.

The Result

In one North Sea example, a liquid H2S scavenger was re-engineered to allow control of H2S levels. The result was a 70% lower dose than the original product. The increased product effectiveness has led to 49,000 fewer gallons of fuel required for transportation and has generated an annual saving of 36 metric tonnes CO2. This equates to 1.35MM litres of product saved annually.

In another example, a combination product, merging the effectiveness of three products into one, was implemented in a multi-point injection and modular tank design – achieving a CO2 reduction of 55 metric tonnes per year. In addition, the number of injection skids was reduced by approximately 100, lowering maintenance activities on location by 60%.

‘…increased product effectiveness has led to 49,000 fewer gallons of fuel required in terms of transportation, and has generated an annual saving of 36 metric tonnes of CO2’

Mark Zijlstra, Regional Manager

Find out more:

Contact: Mark Zijlstra