The power of preservation: putting ‘lost’ energy to new use

A new energy recovery system applies technology used in space exploration and Formula One racing to reduce rig power consumption by up to 80% during key operations.

The Challenge

Capitalising on energy regenerated during heave compensation or tripping operations on offshore drilling units.

Such rigs have traditionally been unable to make use of the energy created when lowering a load – but preserving lost energy would help to reduce fuel costs and emissions while bolstering operational safety and reliability.

The Response

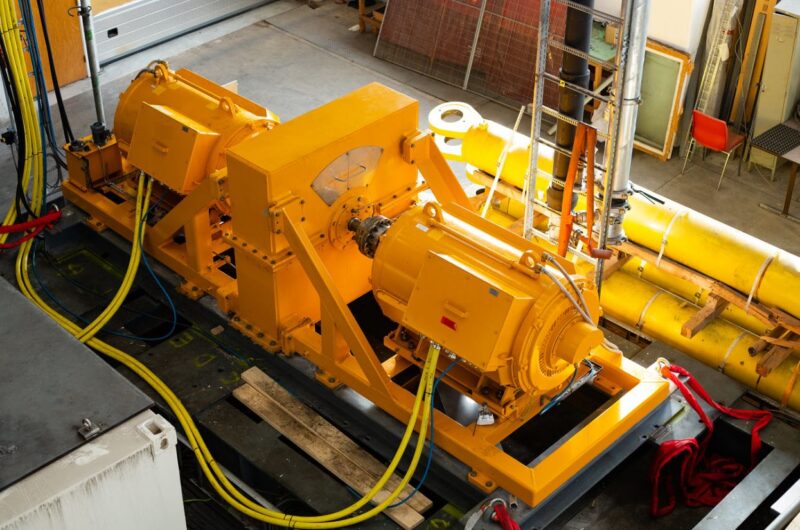

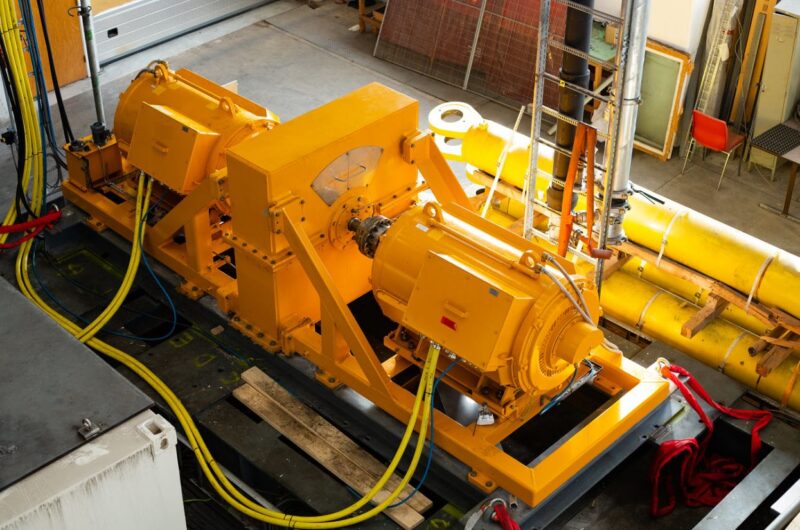

NOV has introduced PowerBlade™, an innovative energy storing and regeneration unit that receives and provides energy based on operational needs.

Developed in partnership with Odfjell Drilling and supported by the Research Council of Norway, the hybrid technology enables the rig to use the energy regenerated in a heave compensation or tripping operation, instead of allowing it to dissipate.

Serving to reduce the diesel engine running hours on the rig, PowerBlade works by absorbing the braking energy emitted when a drill is lowered – and then storing and reusing that energy for the next hoist of the drill string.

PowerBlade harnesses technology used in Formula One racing vehicles and NASA exploration spacecraft for recovering a moving vehicle’s kinetic energy while braking and storing it in a reservoir (or flywheel) for later use under acceleration.

NOV’s hybrid solution combines the best of flywheel and battery options: its flywheel technology supports highly cyclic energy demands typically experienced during heave compensating without affecting the battery lifespan. And the battery package supports activities that have prolonged energy demands, such as tripping operations.

These two technologies combine to cut energy demand related to drilling operations through peak shaving – resulting in less fuel consumption, reduced environmental footprint, reduced generator maintenance and increased energy efficiency.

In short, PowerBlade demonstrates how emissions reduction technology is helping the industry towards a net zero future.

The Result

PowerBlade reduces power consumption on a rig by up to 80% in active heave compensation mode when compared to traditional techniques.

During the product development and full scale testing a study was conducted with drilling data from the previous year’s operation on the semi-submersible Deepsea Atlantic. The direct and indirect result from the testing included a saving for the drilling partner of 6.7 tonnes (8,000 litres) of diesel, which equated to a 25% reduction in daily rig fuel consumption), 17 tonnes of CO2 and 300kg of NOx per day.

‘…direct and indirect impacts included a saving… of 6.7 tonnes of diesel, 17 tonnes of CO2 and 300kg of NOx per day’

The PowerBlade technology was among the 2020 winners in the OTC Spotlight on New Technology awards programme, which highlights the latest technological innovations transforming the offshore sector.

Find out more:

Contact: