Glen Lyon has 4 gas turbines which typically run of fuel gas to provide electrical power to the plant. Each turbine is duel fuel meaning they can also operate on diesel.

In order to check this duel fuel facility each unit is run on diesel for four hours each month. This is to perform a number of key performance checks while on a liquid fuel. The Glen Lyon team identified that these checks could be performed in 15 minutes. Reducing the duration of diesel combustion by 3.75 hours. This change gas now been formalized on the FPSO and lessons shared with other BP assets for implementation where possible.

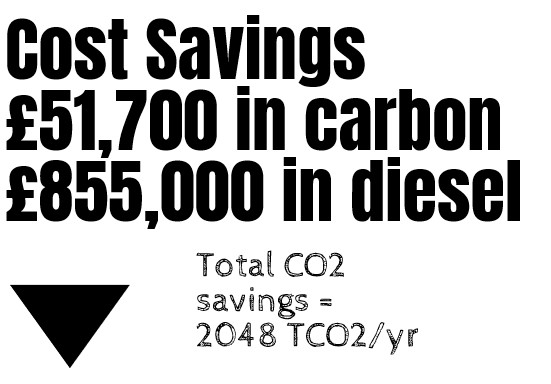

| Cost Saving = £51,700 in Carbon + £855,000 in diesel Diesel saving = 1710 M3/yr Total CO2 saving= 2048 TCO2/yr |

|||

| Fuel | Hours | CO2 per test | CO2 per year |

| Diesel | 0.25 | 7 | 373 |

| Gas | 3.75 | 68 | 3549 |

| Diesel | 4 | 115 | 5970 |

| Gas | 0 | 0 | 0 |

| Total Saving | 2048 |

By replacing diesel combustion with Gas combustion the mass of CO2 is reduced as per tonne, diesel emits more CO2 than Gas. Further more Gas has a higher energy value so less gas needs to be burnt to generate the same power as diesel

In addition to Carbon and diesel savings, this change prevent the turbine burners being choked up so quickly and make efficiency savings through not having to needlessly replace the burners, changeout diesel filters and time saving within the electrical technician’s week.

This improvement was Identified and executed through BP’s Challenge , Check and Change initiative

Share this article