Challenges in Gigawatt-Scale Floating Wind Installations

Apollo and DOF studied key installation challenges for Gigawatt-scale floating wind farms for ORE Catapult.

Executive Summary

Apollo, in collaboration with DOF for ORE Catapult, conducted a comprehensive study addressing the challenges and solutions for installing a Gigawatt-scale floating offshore wind farm. The study focused on cost, schedule, and innovative methodologies to overcome critical installation bottlenecks. This case study delves into the specific challenges of scaling from current demonstrator projects to Gigawatt-scale installations, providing detailed insights and recommendations to improve efficiency and reduce costs.

Challenge

Installing a single state-of-the-art floating offshore wind turbine (FOWT) with its mooring lines and infield cables is a significant offshore marine operation. Scaling this up to develop a Gigawatt-scale floating wind farm, requiring sixty FOWTs, presents a major challenge of scale. This scale-up from 10MW to 100MW demonstrator projects involves substantial logistics, cost, and scheduling complexities, with critical bottlenecks identified in the availability of capable vessels and weather-related delays.

Solution

Apollo and DOF developed a detailed study to address these challenges. Focusing on a representative 100m water depth, 900 MW ScotWind site, the study explored methodologies, schedule, and cost implications.

The solution involved:

- Developing a ‘base case’ installation method by scaling up current practices.

- Exploring ‘future case’ installation scenarios for their potential impact.

- Identifying approaches to accelerate the schedule and protect against emergent delays, such as using taut nylon moorings and smarter risk-based anchor tensioning requirements.

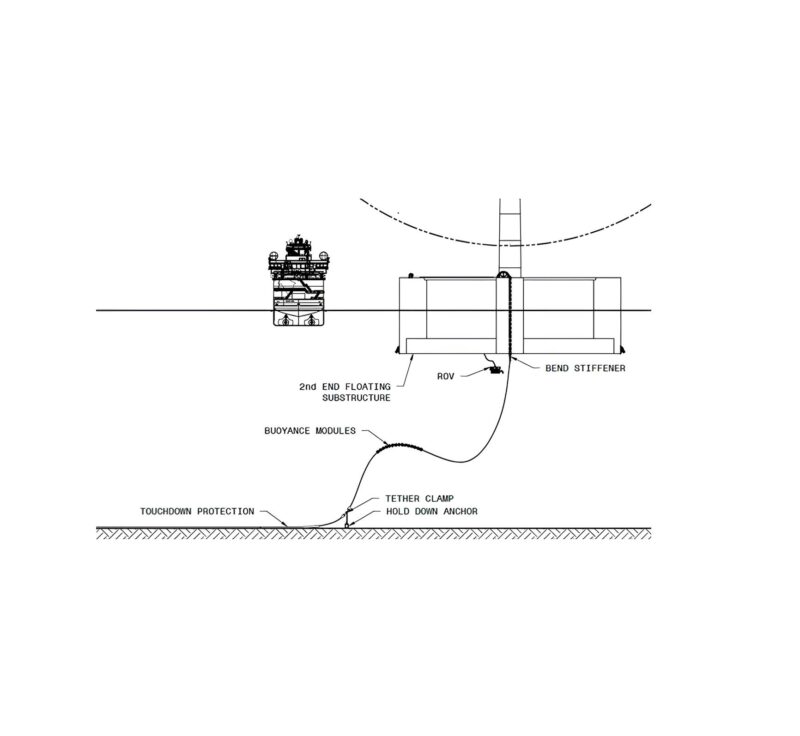

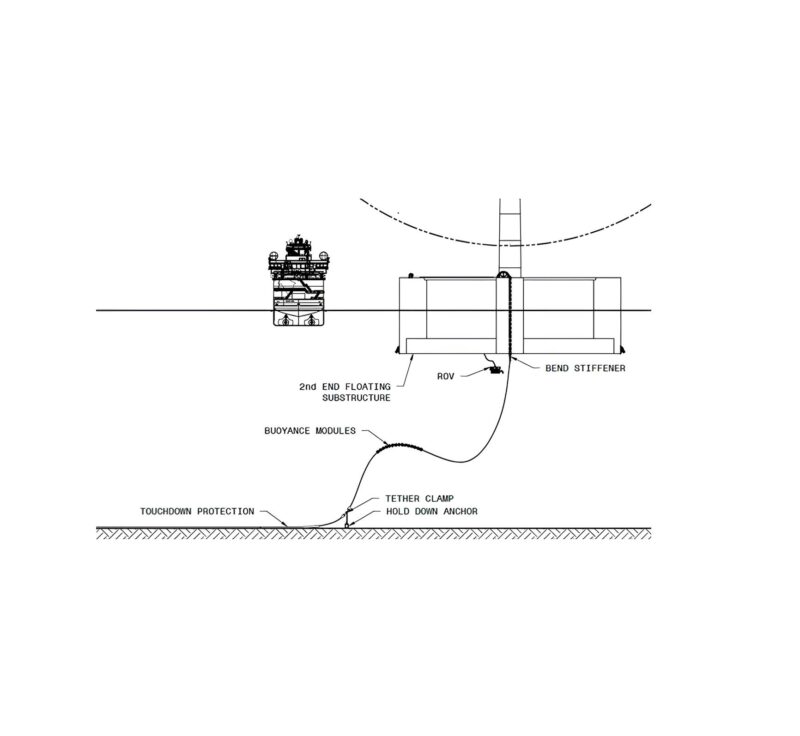

- Proposing a novel installation method modelled on O&G umbilical installation to halve cable pull-in time and reduce costs.

- Recommending quick connect systems to reduce cable pull-in costs further and optimise installation and maintenance.

Results

The study provided critical insights into the gigawatt-scale installation process, enabling developers to make better decisions. Key results included:

• Identification of major bottlenecks, such as the availability of AHTS vessels capable of handling 175mm chain.

• Recommendations for innovative mooring and cable system designs to reduce costs and installation time.

• Detailed methodologies for accelerating the installation schedule and mitigating delays.

The findings will inform project front-end engineering design (FEED) and technology development activities, aiding in the efficient and cost-effective deployment of gigawatt-scale floating offshore wind projects.

Additionally, the study estimated significant cost savings through optimised installation methods. The novel installation method and quick connect systems could reduce installation costs by millions of pounds, though exact figures require further detailed financial analysis.

For more information and to access the full report, visit: https://fowcoe.co.uk/industry-insights/reports/gigawatt-scale-cable-and-mooring-installation/